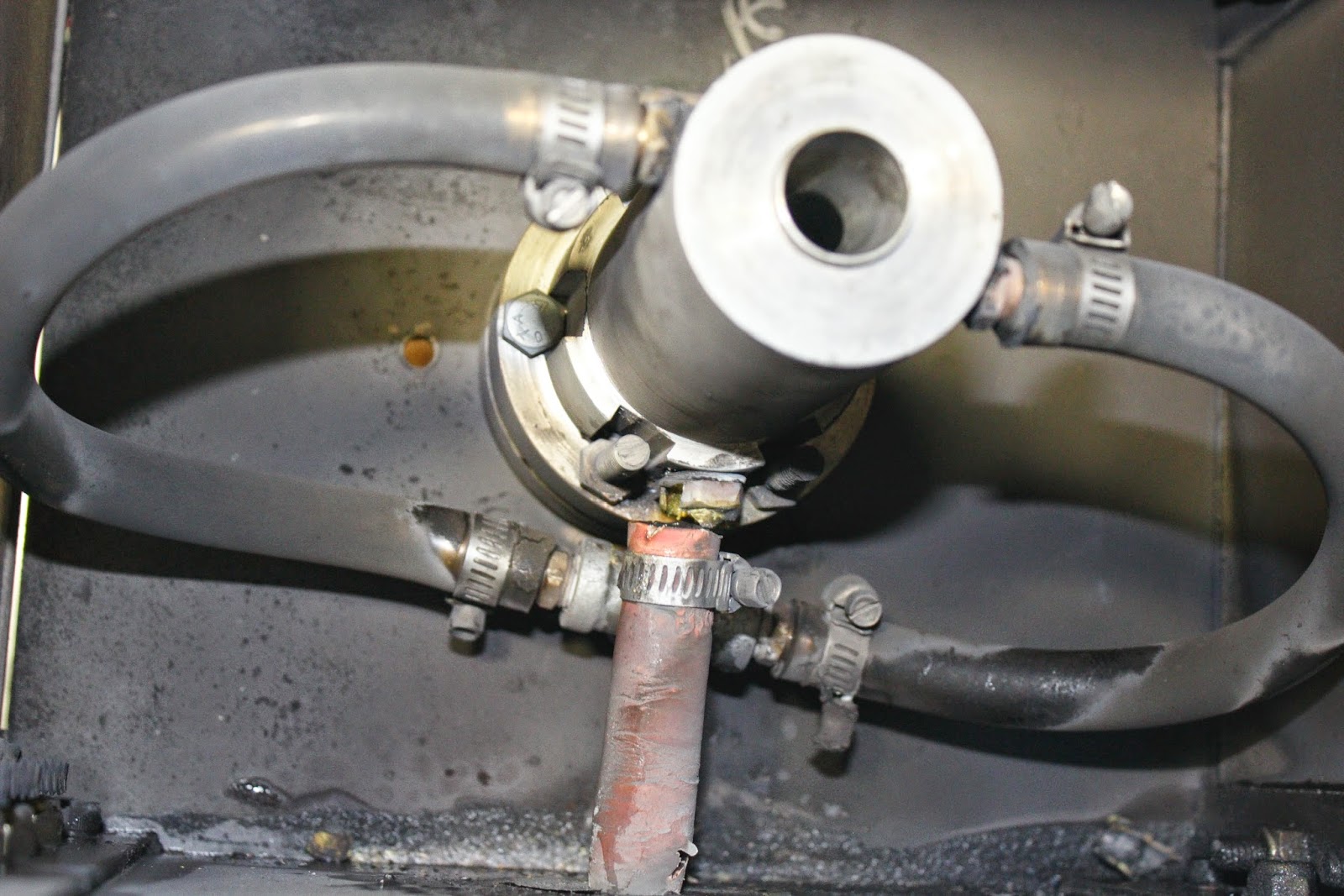

Surprisingly the coolant line burst and the brass fitting exploded.

This was the same hose that blew up in my face a few weeks ago.... apparently it is back for round two!

Its fairly safe to let the excess methanol burn off.

First look inside the combustion chamber

The injector plate is unscathed.

One good note is that the hottest part of the rocket (throat/nozzle) are completely untouched.

Exactly what I thought would happen happened. When I mounted the rocket on the thrust stand, I noticed that water was leaking into the chamber. I spent two days running through the scenario in my head and what happened is that the coolant is ~50 psi and the chamber is 300 psi. The hot gasses pushed their way around the gap and into the coolant line which causes the water to boil. The steam doesn't cool at all so a hot spot forms which melts the aluminum. This progressed along the chamber wall until the hole was over the coolant outlet. The pressure then pushed its way into the line which cause the explosion and exploded the fitting.

Now that I know the concept works (when everything is sealed properly) onto V2!

I read your blog posts in the last hour.Thank you for helping people get the information about heavy machines edge banders they need Keep up the great work!!!

ReplyDelete